Millermatic 355 w/EZ-Latch Running Gear 951926

The Millermatic 355 is perfect for fabrication, manufacturing, maintenance and repair. Auto-Set™ Elite technology allows you to use preset welding parameters based on metal thickness, shielding gas and welding wire type to achieve optimum welds. You can also set your voltage and wire feed speed manually and save your favorite settings for a custom welding experience. Pulsed-MIG welding capability provides even better weld quality and improved productivity on all metals, including thin-gauge aluminum and stainless steel.

EZ-Latch™ running gear with single cylinder cylinder rack gives unmatched portability to the Millermatic 355. For moving around the shop, the 355 attaches to the running gear through a series of four, quick-disconnect latches. For times when your 355 is taken into the field, the machine and running gear can be quickly separated for loading into a vehicle. The 355 can also be separated from the EZ-Latch running gear to access difficult-to-reach areas around the shop where a welder with full running gear/cylinder rack might not otherwise fit.

NOTE: EZ-Latch™ running gear comes in separate box and requires some assembly. Components assemble in three steps and include: cart with front caster wheels, cylinder tray with rear wheels and cylinder post.

![]()

Processes

- MIG (GMAW)

- Pulsed MIG (GMAW-P)

- Flux Cored (FCAW)

Applications

Industrial Applications

Fabrication

Maintenance and Repair

Manufacturing

Features

- EZ-Latch™ single cylinder running gear

Provides unmatched portability for the Millermatic® 355. Operators no longer need to lift machine AND running gear when loading or moving. Latches secure machine to running gear. Simply loosen the latch retaining knob and rotate latches to disengage machine from running gear for easy portability. Cylinder rack features bottle forward technology for increased stability when moving along an incline and running gear has built-in storage for accessories. - Easy-to-understand interface with 7-inch color LCD display

Ensures proper machine setup and parameter selection, reducing setup time and increasing weld time. Quick-access backlit Auto-Set and Pulse buttons above the LCD display illuminate when active. Soft-key buttons below the display change function depending on which screen is displayed. Makes setup or change quick, easy and intuitive. Large text for easier readability. Intuitive connection setup images. Full troubleshooting descriptions versus help errors and look up codes.

- Auto-Set™ Elite offers predefined weld settings to increase ease of use and ensure that the job is done right for operators of all skill levels. Available for MIG and pulsed MIG processes with the ability to fine-tune your settings. Set weld parameters by selecting wire and gas type, wire diameter and material thickness.

- 1- or 3-phase input power

Provides versatility to utilize any North American power (208, 230, 460, 575 Volts). - Program mode

Allows easy save and recall of favorite weld settings.

Delivers greater productivity by eliminating the need to manually set or change parameters.

Delivers consistent quality by welders of all skill levels by using prequalified weld settings.

Minimizes supervisor need to intervene. - Trigger program select

Increases productivity by eliminating the need to go back to machine to change weld settings. Simply tap gun trigger to select the program. - Pulsed MIG welding

Delivers higher quality welds for ALL welders.

Lower heat input for less distortion on thin materials and better puddle control on out-of-position welds.

Less spatter minimizes post weld grinding and rework allowing more welding time.

Perform welding applications that couldn’t be done in the past.

Ideal for MIG welding aluminum and stainless steel.

- Superior aluminum performance.

Direct connection for OPTIONAL XR™ push-pull guns or Spoolmatic® spool guns.

Auto-Gun Detect™ automatically adjusts voltage, wire speed and timers for faster switching between MIG, push-pull and spool guns. - Industrial, 4-roll wire drive system

Features two easy-to-set, scaled, tension adjustments and quick-change reversible drive rolls for .035 and .045 in (0.9 and 1.2 mm) wire. - Input voltage selection

Switch located in the wire drive compartment provides the ability to manually switch input voltage. An error message will be displayed if the wrong input voltage is utilized. - Generator compatible

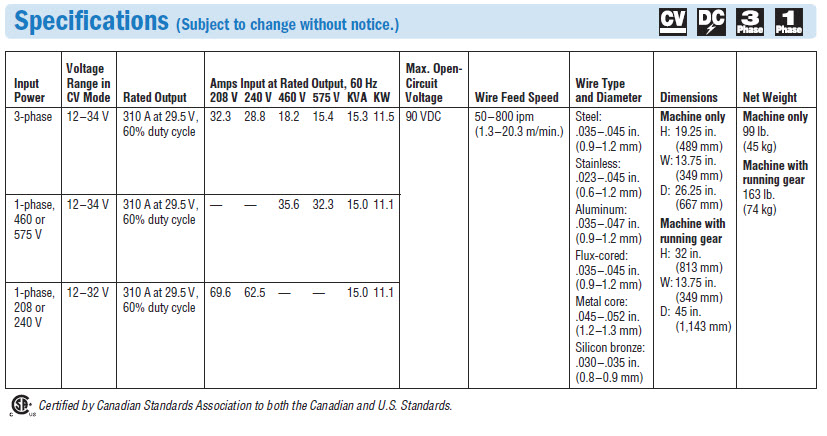

The Millermatic 355 will be able to operate and provide full output when powered by generators with 19,000-watt (19 kW) output or higher. Limited output will occur when used with smaller generatorsSpecs

Comes complete with:

- Millermatic® 355 MIG Welder

- EZ-Latch™ single cylinder running gear

- Cylinder chain

- Bernard® BTB 300 MIG Gun with AccuLock™ consumables

- Industrial power cord (without plug) for single- or three-phase

- Work cable with clamp

- Factory-installed gas solenoid

- Argon mix regulator/flow meter

- .035/.045 Drive rolls and contact tips

- FREE Optrel® Panoramaxx CLT Silver auto-darkening welding helmet

Reviews

There are no reviews yet.