Miller XMT 650 ArcReach 460V Multiprocess Welder 907823

The secret to ArcReach technology is built-in circuitry in both the XMT 650 ArcReach welder and OPTIONAL ArcReach wire feeder/remote control, that passes remote control signals through the welding leads, eliminating the need for costly remote control cables. ArcReach remote control distance is limited only by the length of your welding cable leads. ArcReach allows your MIG or Flux-Cored welding operation to take place further away from the welding power source and reduces downtime and costs by giving the operator full remote voltage and amperage control capabilities at the site of the weld without using expensive remote control cables. The XMT 650 ArcReach MUST be paired with a Miller ArcReach feeder or ArcReach Stick/TIG remote to get the full benefits of this feature.

The XMT 650 ArcReach is specifically designed for heavy duty welding in the structural steel, building construction and ship building industries. It has a corrosion-resistant aluminum case and is very electrically efficient. The has excellent stick and Lift-Arc™ TIG arc characteristics. It also has excellent short-arc MIG characteristics for precise thin metal welding performance

![]()

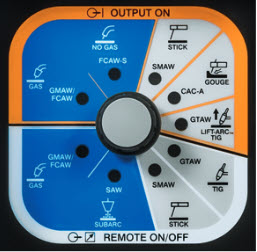

Processes

- MIG (GMAW)

- Stick (SMAW)

- DC TIG (GTAW)

- Flux Cored (FCAW)

- Air Carbon Arc (CAC-A) Cutting and Gouging (through 3/8 in carbons)

- Submerged Arc Welding (SAW)

Applications

Heavy Industrial Applications

Fabrication and construction

Heavy manufacturing

MRO maintenance/repair

Pressure tank/vessel fabrication

Shipbuilding

Refineries and foundries

Rail car manufacturing

Earth-moving equipment manufacturing

Features

- Remote control of the power source without a cord

ArcReach™ technology uses the existing weld cable to communicate welding control information between the Miller® ArcReach® feeder or ArcReach® Stick/TIG remote and power source. This technology eliminates the need for control cords, and their associated problems and costs. - Remote in use indicator

Provides convenient feedback indicating an ArcReach® wire feeder is controlling the power source.

While under ArcReach control, process and voltage/ amperage adjustments are locked out, preventing accidental changes by personnel other than the welding operator. - Auto Remote Sense™

Enables unit to automatically use remote control if connected to remote control receptacle. - 14-pin receptacle

Has the flexibility to be used with spool guns, feeders, and remote controls. - Arc control

Is active in the stick and solid-wire processes.

It allows the operator to customize arc characteristics to match preference, electrode and joint design from a softer arc with more fluid puddle to a stiffer arc with a more controllable puddle.

The Star setting is optimized for most applications and pointing the control at Soft or Stiff is optimal for most arc preferences.

Control is fully adjustable from 0 to 25 Soft or 0 to 25 Stiff.

- LED process indicator

Front panel process selections are illuminated with an LED that identifies the active process.

This enables the selected weld process to be seen at a distance from the power source. - Gouging mode is an optimized stick position for better gouging performance

- Three wire modes (GMAW/FCAW/SAW) for simplified setup and optimized arc performance

– Solid and flux-cored wires with gas

– Flux-cored (self-shielded)

– Sub arc - Stick mode for all electrode types

- Lift-Arc™ TIG

- Back panel

15 amps of 120-volt power to run power tools

PLUS – get a FREE Optrel® Panormaxx CLT Silver auto-darkening welding helmet with the purchase of this Miller® XMT™ 650 ArcReach®welder. While supplies last. (No substitutions allowed.)

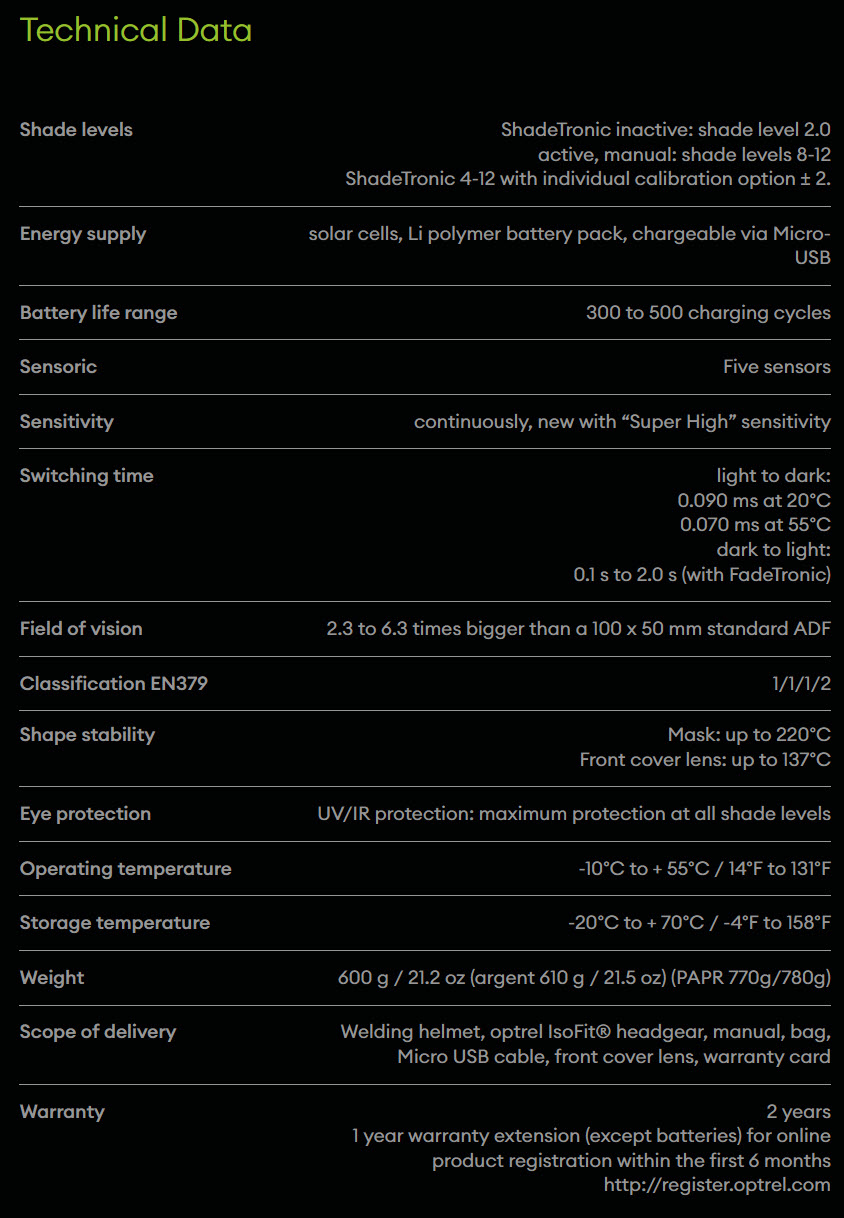

The Optrel® Panoramaxx CLT Silver auto-darkening welding hood features Crystal shade 2.0 light state that is unmatched in the world for color and clarity and provides up to 6X the viewing area of a standard 2″ X 4″ auto-dark welding lens. The key to this revolutionary technology is the size and shape of the ADF, coupled with the unique Panoramaxx shell design, which allows the welding lens to be positioned closer to your face. The Panoramaxx also has advanced features like SHADETRONIC®, which automatically adjusts the shade level based on the brightness of the arc and True Color, which allows for realistic color perception in light or dark states.

All Panoramaxx welding helmets now come with the revolutionary IsoFit® headgear. It is the only welding headgear in the world that wraps the entire crown of the head with multiple touch points to provide a custom fit like never before. Independent “three dimensional” size, width and height adjustments ensure all day comfort with a secure hold.

The Panoramaxx CLT has a built-in rechargeable battery that does not need replacing. The battery is charged through arc light or when manual charging is necessary, a micro USB charging port. It comes complete with micro USB cable, helmet bag and Oprel’s 2+1 warranty.

Features

- PANORAMIC FIELD OF VISION – The Panoramaxx CLT offers a 6 times larger field of vision than standard welding helmets – and is still a lightweight at only 21.5 ounces.

- CRYSTAL LENS TECHNOLOGY 2.0 – Shade 2.0 light state provides the brightest view of your working environment available anywhere. The natural color and clear optics supplied by CLT increases both safety and efficiency in the workplace.

- SHADETRONIC® – Detection of the arc brightness and fully automated shade level adjustment from 4 to 12. Adjusts automatically to the changing light conditions of the current welding method. A sophisticated SHADETRONIC® sensor continuously measures the light intensity of the welding arc and regulates the glare protection progressively and fully automatically.

- FADETRONIC – Patented Optrel FadeTronic technology gradually lightens the auto darkening filter after the welding arc is extinguished. The unpleasant afterglow is faded out – especially for high amperage applications. Eye fatigue is significantly reduced, enhancing worker safety. FADETRONIC can be adjusted for a custom user experience.

- TRUE COLOR – A specially developed UV/IR filter allows the realistic color perception typical of Optrel®, bringing color to the welder’s world. TRUE COLOR passes more colors of the spectrum through compared to standard “green” spectrum welding lenses.

- Optrel Re-Charge – With its rechargeable power-pack, changing batteries is no longer necessary. Thanks to the latest solar technology, a rechargeable lithium-polymer battery is recharged either by the welding light or by the ambient light. In addition, the battery can also be charged directly with any USB charger via a micro-USB interface.

- 5-Point Detection – intelligent sensor control with five sensors. Sophisticated software and clever positioning of four sensors at the corners and one sensor in the upper center ensures the lens is switched on and off perfectly, even in the most difficult lighting conditions or in awkward positions.

- IsoFit® headgear sets a new standard of wearing comfort. It is the only product worldwide that can be adjusted in width, length and height – i.e. three-dimensionally – to any head shape, so that the helmet really fits “like a glove.”

- FadeTronic® – gradually lightens lens when switching from dark (welding) to light state to ease eye fatigue.

- Sensitivity Adjustment – allows operator to change lens switching sensitivity for varying ambient light conditions or outdoor welding in sunlight.

- Grinding Mode – external grind control allows user to switch between welding mode and shade 2 grinding mode quickly and easily.

- Delay Function

- Out-Of Position Welding is possible with Optrel®’s unique shell design, which has no seams or edges where weld spatter can collect.

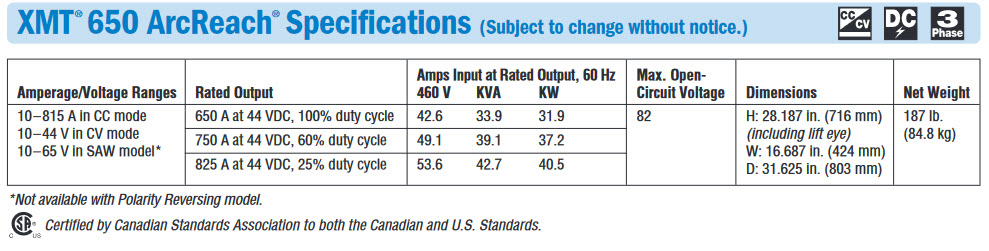

Specs

Comes complete with

- Micro USB charging cable

- Helmet bag

- 1 extra outside cover plate

- 2+1 warranty

Reviews

There are no reviews yet.