Millermatic 211 MIG Welder With Advanced Auto-Set And Cart 951603

Manual MIG welding control is also available for those welders who wish to fine tune their welding arc. The parameter door chart lists voltage and wire feed speed settings options.

The included heavy-duty welder cart/cylinder rack has eight inch rubber wheels in back and front casters for easy maneuvering. The gas cylinder rack is designed to hold one shielding gas cylinder no larger than 7 in (178 mm) diameter, maximum weight 65 lb pounds (80 cubic foot capacity is ideal)

![]()

Processes

- MIG (GMAW)

- Flux Cored (FCAW) (gas and self-shielded)

Applications

Light Fabrication

Maintenance and Repair

Auto Body

Farm/Home

Features:

- Advanced Auto-Set™ – now includes five different wire/gas combinations and .024-inch (0.6 mm) wire capability. The easiest welder to use just became more versatile.

- Wire/gas combinations include Flux Cored, Mild Steel with 100% CO 2 , Mild Steel with C25, Stainless Steel, and Aluminum with spool gun

- Select the wire type and gas being used

- Set the wire diameter, and select from .024, .030 and .035 diameters. A blue LED indicates that Auto-Set is activated

- Dial in the thickness of what you are welding

- Start welding with the exact parameters you need!

- Miller inverter technology combines best-in-class arc characteristics with the portability of a 38-pound machine. The arc is extremely forgiving to variations in arc length and travel speeds

- Angled cast-aluminum drive system with calibrated tension knob creates consistent feeding and easy setup for up to 15-foot MIG guns.

- Quick Select™ drive roll makes setup quicker by offering three grooves, two for different size solid wire and a third for flux-cored welding wire.

- Auto Spoolgun Detect™ automatically detects when a MIG gun or spool gun is connected eliminating the need for a switch.

- Smooth-Start™ provides a smooth, spatter-free start. It is the best-starting machine in the small MIG machine category.

- Fan-On-Demand™ power source cooling system operates only when needed, reducing noise, energy use and the amount of contaminants pulled though the machine.

- Thermal overload protection shuts down unit and activates the over temperature light if airflow is blocked or duty cycle is exceeded. Automatically resets when unit cools.

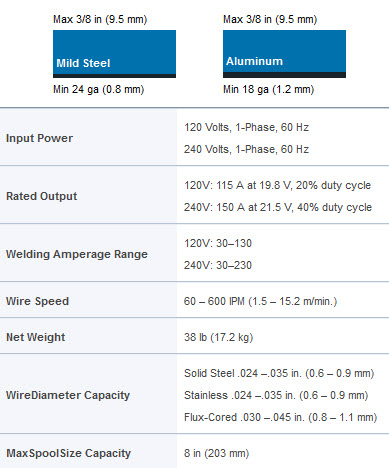

- Uses 4 inch or 8 inch (102 or 203 mm) spools and can be set up to weld with .024 to .035 inch (0.6 to 0.9 mm) solid wire and .030 to .045 inch (0.8 to 1.1 mm) flux-cored wire.

Specs

Comes complete with:

- Millermatic® 211 MIG welder

- Running Gear/Cylinder Rack #301 239

- 6.5-ft. (2 m) power cord with MVP plugs for 120 V and 240 V

- 10-ft. (3 m), MDX™-100 MIG gun and cable assembly

- 10-ft. (3 m) work cable with clamp

- Argon – Argon/CO2 mix flow gauge regulator with gas hose

- Hobart® spool of .030-in. (0.8 mm) solid wire

- Two contact tips for .030-in. (0.8 mm) wire

- Quick Select® drive rolls for .024-in. (0.6 mm) or .030/.035-in. (0.8/0.9 mm) solid wire, and .030/.035-in. (0.8/0.9 mm) flux-cored wire

- Material thickness gauge #229 895

- Velcro cord wraps

- FREE Miller® Classic ClearLight™ Black VS welding hood.

- FREE Hobart® Fabshield® 21B 2 lb. spool .035 E71T-11 flux-cored welding wire.

Reviews

There are no reviews yet.